Strengths and Weaknesses of Industrial Cart Connection Methods

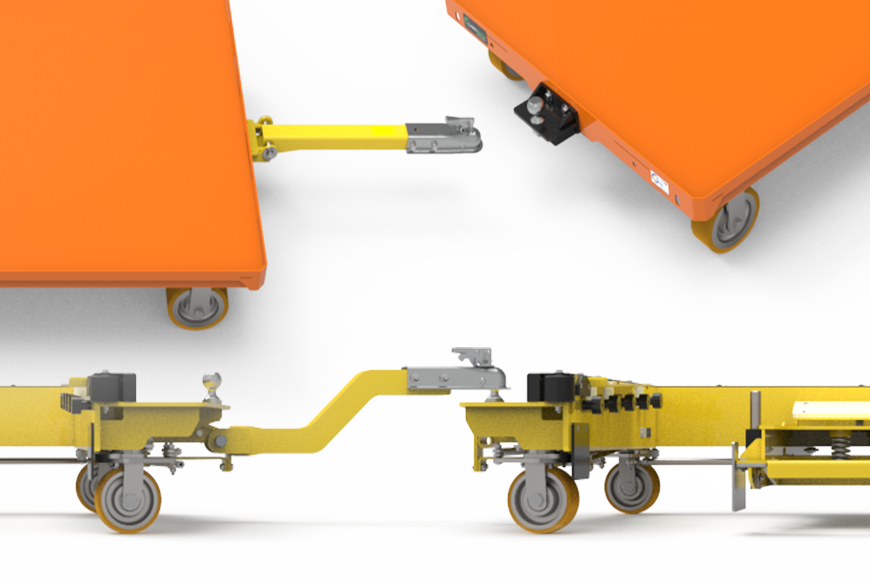

Ball Hitch & Coupler

Strengths: Secure connection: The ball joint is secured by a lever which locks the coupler in place. The lever is also then locked in place with a wire-lock pin, creating a failsafe redundancy. A secure connection lowers the risk of a tugger cart decoupling during transit.

Tight connection: There is almost no “slop” in the connection joint which has several important benefits. There will be little to no jerking when accelerating from a static position or when decelerating. This improves a tugger operator’s working environment and comfort. Along with no jerking, there is reduced noise caused by the train during takeoff and when coming to a stop. Many manufacturers look for these kinds of unique solutions to reduce a factories ambient noise level. Finally, a tight connection greatly increases the tracking performance of the entire train when compared to a loose connection joint. Space is a valuable resource within manufacturing facilities. A cart train with an increased tracking performance allows the plant to reduce aisle widths and increase value added manufacturing space, improving the bottom line.

Weaknesses: Decreased ergonomics: Hitching and unhitching carts with a ball and coupler can often require an operator to bend over for a slightly longer period when compared to other connections. A happy operator is typically a productive employee. If frequent coupling and decoupling is required to support the process, it behooves the plant engineering team to evaluate other connection methods.

Less commonly utilized: It is preferred to have a single hitching method at a plant to reduce the overall tugging system complexity and to allow a higher combination of cart types pulled in a train. Many plants do not utilize a ball and coupler as a standard. This may also cause a need for a custom hitch on the tow vehicle.

Lunette Ring and Pin or Pintle

Strengths: Capacity: A lunette ring with pin or pintle can be designed to easily handle the heaviest of payloads when tugging carts. Carts designed to handle loads of 10,000# + usually utilize a ring and pin or pintle.

Versatile: The lunette ring tongue may be used with a pin, pintle, or alligator hitch. This versatility makes it a frequent choice in many plants. As previously stated, this allows for a higher likely hood of being able to combine different carts from different manufacturers, in a single train.

Common use: Many cart & hitch manufacturers utilize this design. Therefore, a custom hitch on the tugging vehicle is usually not required like you may see with ball & coupler.

Weaknesses: Decreased ergonomics: While slightly more ergonomic than a ball and coupler, this connection method does usually still require an operator to bend over for a period.

Loose connection: Opposite to the points highlighted in the ball & hitch tight connection pros, a loose connection contributes to increased plant noise, poorer tracking performance, and reduced tugging operator comfort. This may cause wider aisles, a noisier factory environment, and frustrated tugging operators.

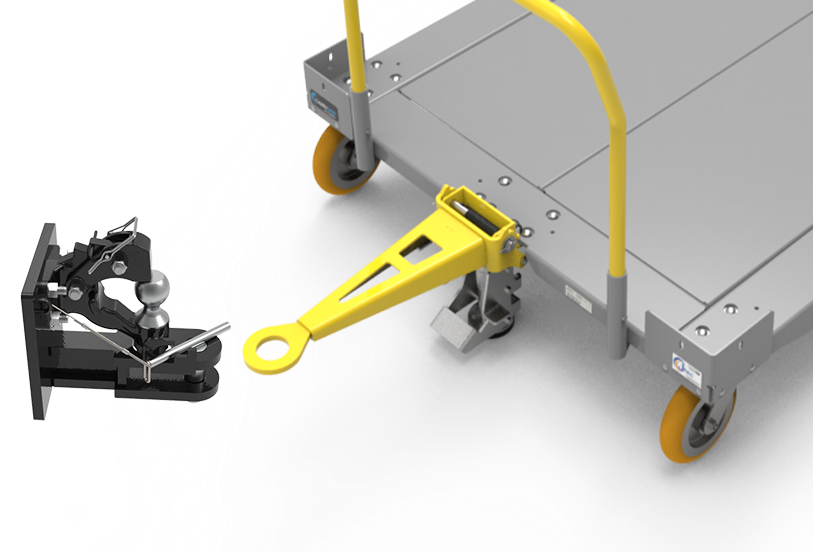

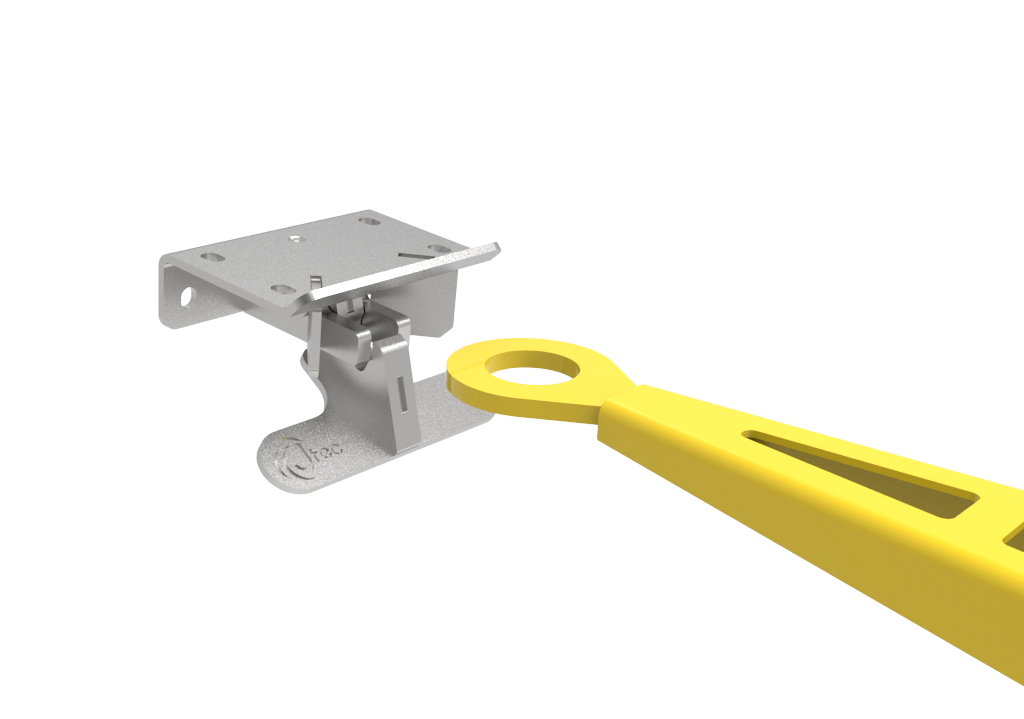

Lunette Ring and Alligator Hitch

Strengths: Versatile: As stated above, a lunette ring allows for the tongue to mate with various other hitching methods. Such as pin and pintle. However, the alligator hitch usually only accepts specific sized lunette ring tongues.

Ergonomic: This connection method is the most ergonomic of all varieties mentioned. The design allows for hitching and unhitching carts without bending over.

Efficient: An alligator hitch is designed for the purpose of quick connect and disconnect. Once experienced an operator will unhitch and hitch these carts much faster than other connection methods mentioned.

Weaknesses: Capacity: An alligator hitch is typically designed to support a lower payload than ball & coupler and ring + Pin/Pintle.

Less secure connection: The quick release feature of the alligator hitch relies on the constant pressure of a spring. Over time, a spring may weaken or even fail. This can compromise the security of the connection. While all hitches should be inspected regularly, a maintenance tech should take extra care in inspecting the spring feature of the alligator hitch.

Loose connection: The slop found in an alligator hitch is typically less than what is found in ring or pintle. However, it is still much greater than what you would find with a ball and coupler. This will still drive less than optimum conditions for operator comfort, noise, and tracking performance.

Questionable safety process: The quick connect design, while very ergonomic, does usually require an operator to take one of the feet off the ground while connecting or disconnecting. This can be seen as a hazard depending on different facilities safety practices.

Summary

Jtec utilizes all these various connection methods discussed above, and more. It is easy to see why we choose the ball & coupler for our patented CarryMore Mother Daughter Tugger Cart System. Because a mother cart train is rarely unhitched, this allows us to take advantage of all of the benefits of the ball and coupler connection method, while still achieving efficient and ergonomic exchanges of daughter carts via our patented Elemate technology.

Contact Jtec Industries for more information about how you too can begin realizing the many benefits of Tugger Carts and other Jtec products.