Autonomous Carts, stations & software

POWERED CONVEYOR

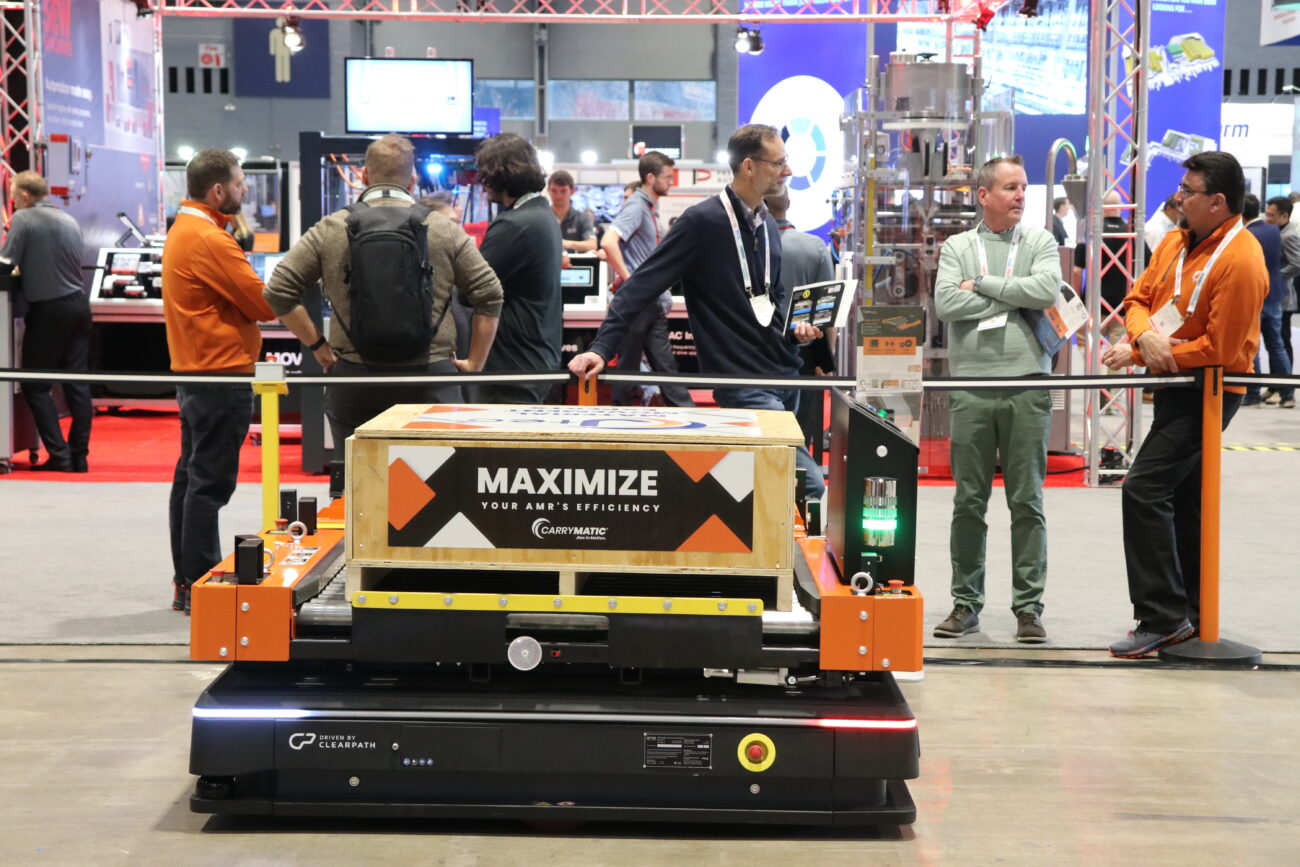

AMR ATTAchments

Data server carts

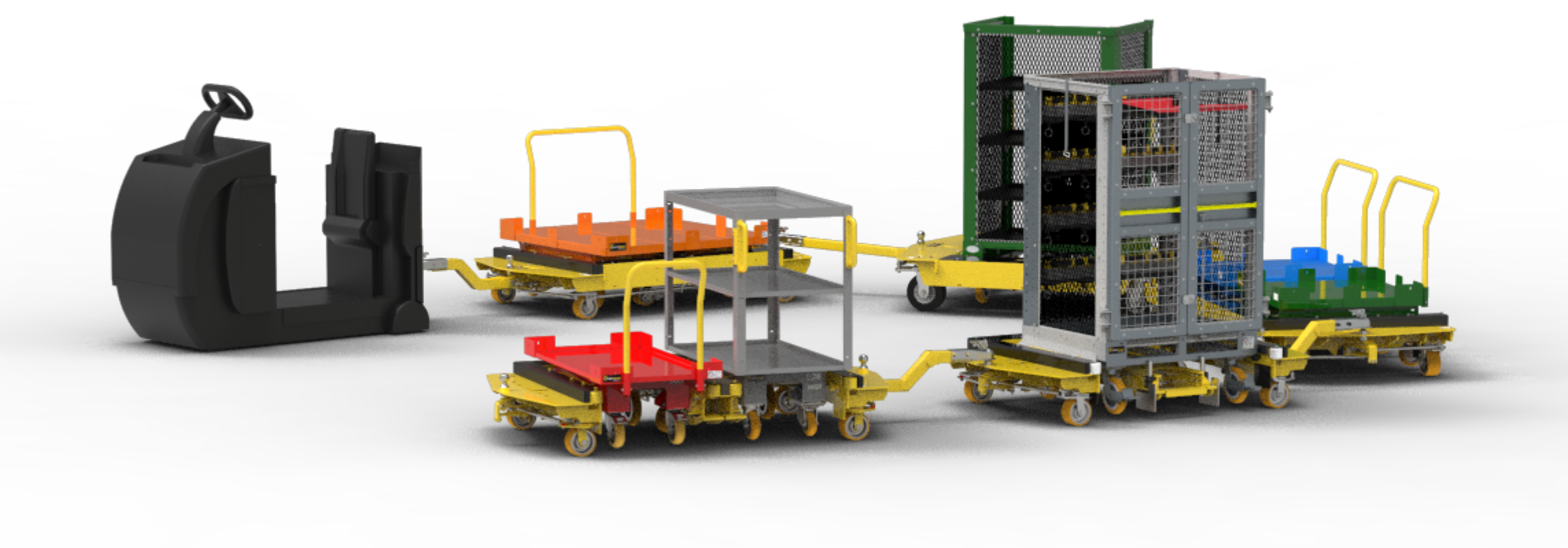

Single or dual bay carts

Choose the configuration that best fits your needs. Single bay carts provide tight aisle access while dual-bay carts maximize payloads.

AMR Compatible

This plug-and-play system works with existing AMRs and can be easily integrated with a facility's existing system.

Electric Lift Mechanism

Raises your server racks 1 inch above the ground. This compact and efficient system is designed to facilitate the safe and easy transport of server equipment.

Custom configuration

We have always risen to the challenges presented by our customers. We have thousands of previous designs to start from and years of experience to meet your fit, form, and function needs.

Supervisor Software

Communicates with the AGV supervisor and other auxiliary control with the system to facilitate proper transfers.

Versatile Logistics Solution

Standard design is available to accommodate both the ORv2 & ORv3 server racks in the same cart. Customized options also available.

AGV & System integration

This plug-and-play system works with any brand of AGV tugger and can be easily integrated with a facility's existing system.

Scissor lift & powered rollers

We offer a scissor lift attachment that integrates with our pick-up and delivery stands and a single and dual-bay powered roller attachment that integrates with our PR station and existing stations.

Safety Systems

Carts are equipped with E-Stops on all four corners that are integrated with the AGV's emergency stop system. Also available iwth LiDAR sensor to help protect the cargo and its surroundings.

LEARN MORE

Autonomous carts

CARRYMATIC POWERed conveyor SYSTEM

Get the most out of your AGV investment with this system that can be paired with any AGV tugger along with an integration option for a manual tugger. Click the Learn More button for more details about Powered Roller Carts, Stations, and Controls.

CARRYMATIC Supervisor software

As the “brains” of the CarryMatic system, the supervisor is hardwired into the facility LAN and communicates directly with the AGV supervisor and other pieces of equipment necessary, in the agreed-upon protocol, to transfer material.