Have you ever asked yourself, “Is there a better way to move materials through our facility?” Many companies are still using fork trucks while others are tugging with tongue and hitch style carts and mother/daughter style trains. A growing number of companies are turning to automated delivery systems. The method I am asked about on an almost daily basis (and easily one of the safest and most efficient modes of material movement) is a Mother/Daughter Cart system.

When deciding on a new cart delivery system, you have two options for Mother/Daughter systems:

Option 1: Daughter Cart casters ON the ground

Option 2: Daughter Cart casters OFF the ground.

Although the difference is very simple and straightforward, the benefits of having your daughter carts casters off the ground when in transit versus staying on the ground are abundant! There are a few key factors to think about when considering what’s best for you.

Improve Ergonomics

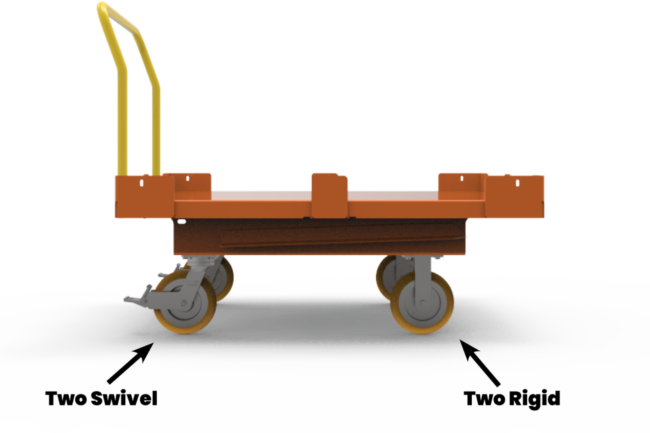

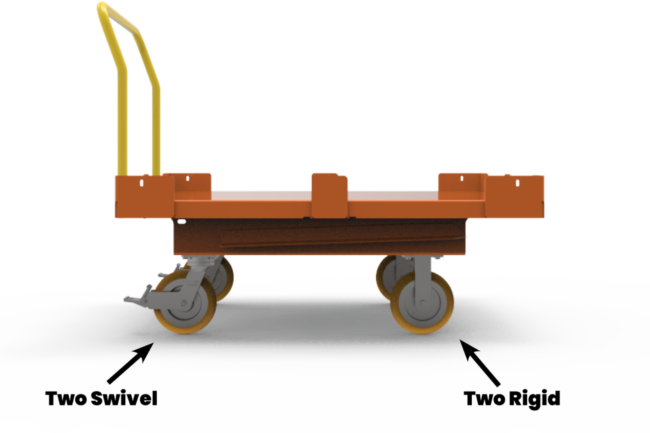

A Daughter Cart riding OFF the ground means it can have two swivel casters and two rigid casters. With carts riding on the ground, all casters must be swivel. So why is this such a big deal? Once that Mother/Daughter train reaches its destination, a Daughter Cart must be released and pushed to its staging area. Whether it is a long or short distance, in a straight line, or around a corner, the level of difficulty and ergonomic strain associated with pushing a cart with four swivel casters are noticeably higher than pushing a cart with two rigid and two swivel casters.

The other ergo benefit associated with casters off the ground is reduced wear and tear. Less ground time = less wear and less wear = better push/pull numbers for a longer period! If this doesn’t get your safety managers on board, let me lead you to the next benefit.

Improve Ergonomics

A Daughter Cart riding OFF the ground means it can have two swivel casters and two rigid casters. With carts riding on the ground, all casters must be swivel. So why is this such a big deal? Once that Mother/Daughter train reaches its destination, a Daughter Cart must be released and pushed to its staging area. Whether it is a long or short distance, in a straight line, or around a corner, the level of difficulty and ergonomic strain associated with pushing a cart with four swivel casters are noticeably higher than pushing a cart with two rigid and two swivel casters.

The other ergo benefit associated with casters off the ground is reduced wear and tear. Less ground time = less wear and less wear = better push/pull numbers for a longer period! If this doesn’t get your safety managers on board, let me lead you to the next benefit.

Cut Expenses

This ties into the last point of reduced caster wear and are very simple….If your daughter cart’s casters see less wear because they are ALWAYS off the ground when in tow, you will not need to replace them near as often possibly never at all! Many of you know, a high-quality caster can make or break a system, and are not cheap to replace! This goes for just regularly scheduled maintenance as well. Less wear=less maintenance time and cost. Who doesn’t love saving money?!

Reduce Noise

Hear me out on this one (Do you see what I did there?). One of the least-discussed benefits to casters off the ground is the reduced noise levels associated with tugging. Simply put – when a Mother/Daughter cart train is being towed with casters on the ground you have wheels on a Mother Cart AND wheels on a Daughter Cart rattling around during towing. A caster OFF the ground Mother/Daughter system takes those Daughter Cart casters out of the equation.

Why is noise such a big deal? A noisy facility is a costly facility. OSHA’s regulations state where the worker is exposed to a weighted equivalent noise level of 85 dBA or more during an 8 hour shift the employer must implement a hearing conservation program. This includes consistently monitoring noise levels, offering free annual hearing tests, and providing hearing protection and training. If your decibel level is close to 85 dBA, having the right casters will make great improvements, but also having those casters off the ground could be the difference in being required to offer a costly hearing conservation program.

I hope this has helped to clarify why Mother/Daughter Cart systems with casters OFF the ground are optimal. Not only are they more efficient, but they can save your company money and reduce noise. Again, ask yourself “Is there a better way?”…..and the answer is YES, Casters off the ground.

Have questions? Contact us!

Cut Expenses

This ties into the last point of reduced caster wear and are very simple….If your daughter cart’s casters see less wear because they are ALWAYS off the ground when in tow, you will not need to replace them near as often possibly never at all! Many of you know, a high-quality caster can make or break a system, and are not cheap to replace! This goes for just regularly scheduled maintenance as well. Less wear=less maintenance time and cost. Who doesn’t love saving money?!

Reduce Noise

Hear me out on this one (Do you see what I did there?). One of the least-discussed benefits to casters off the ground is the reduced noise levels associated with tugging. Simply put – when a Mother/Daughter cart train is being towed with casters on the ground you have wheels on a Mother Cart AND wheels on a Daughter Cart rattling around during towing. A caster OFF the ground Mother/Daughter system takes those Daughter Cart casters out of the equation.

Why is noise such a big deal? A noisy facility is a costly facility. OSHA’s regulations state where the worker is exposed to a weighted equivalent noise level of 85 dBA or more during an 8 hour shift the employer must implement a hearing conservation program. This includes consistently monitoring noise levels, offering free annual hearing tests, and providing hearing protection and training. If your decibel level is close to 85 dBA, having the right casters will make great improvements, but also having those casters off the ground could be the difference in being required to offer a costly hearing conservation program.

I hope this has helped to clarify why Mother/Daughter Cart systems with casters OFF the ground are optimal. Not only are they more efficient, but they can save your company money and reduce noise. Again, ask yourself “Is there a better way?”…..and the answer is YES, Casters off the ground.

Have questions? Contact us!

Improve Ergonomics

A Daughter Cart riding OFF the ground means it can have two swivel casters and two rigid casters. With carts riding on the ground, all casters must be swivel. So why is this such a big deal? Once that Mother/Daughter train reaches its destination, a Daughter Cart must be released and pushed to its staging area. Whether it is a long or short distance, in a straight line, or around a corner, the level of difficulty and ergonomic strain associated with pushing a cart with four swivel casters are noticeably higher than pushing a cart with two rigid and two swivel casters.

The other ergo benefit associated with casters off the ground is reduced wear and tear. Less ground time = less wear and less wear = better push/pull numbers for a longer period! If this doesn’t get your safety managers on board, let me lead you to the next benefit.

Improve Ergonomics

A Daughter Cart riding OFF the ground means it can have two swivel casters and two rigid casters. With carts riding on the ground, all casters must be swivel. So why is this such a big deal? Once that Mother/Daughter train reaches its destination, a Daughter Cart must be released and pushed to its staging area. Whether it is a long or short distance, in a straight line, or around a corner, the level of difficulty and ergonomic strain associated with pushing a cart with four swivel casters are noticeably higher than pushing a cart with two rigid and two swivel casters.

The other ergo benefit associated with casters off the ground is reduced wear and tear. Less ground time = less wear and less wear = better push/pull numbers for a longer period! If this doesn’t get your safety managers on board, let me lead you to the next benefit.

Cut Expenses

This ties into the last point of reduced caster wear and are very simple….If your daughter cart’s casters see less wear because they are ALWAYS off the ground when in tow, you will not need to replace them near as often possibly never at all! Many of you know, a high-quality caster can make or break a system, and are not cheap to replace! This goes for just regularly scheduled maintenance as well. Less wear=less maintenance time and cost. Who doesn’t love saving money?!

Reduce Noise

Hear me out on this one (Do you see what I did there?). One of the least-discussed benefits to casters off the ground is the reduced noise levels associated with tugging. Simply put – when a Mother/Daughter cart train is being towed with casters on the ground you have wheels on a Mother Cart AND wheels on a Daughter Cart rattling around during towing. A caster OFF the ground Mother/Daughter system takes those Daughter Cart casters out of the equation.

Why is noise such a big deal? A noisy facility is a costly facility. OSHA’s regulations state where the worker is exposed to a weighted equivalent noise level of 85 dBA or more during an 8 hour shift the employer must implement a hearing conservation program. This includes consistently monitoring noise levels, offering free annual hearing tests, and providing hearing protection and training. If your decibel level is close to 85 dBA, having the right casters will make great improvements, but also having those casters off the ground could be the difference in being required to offer a costly hearing conservation program.

I hope this has helped to clarify why Mother/Daughter Cart systems with casters OFF the ground are optimal. Not only are they more efficient, but they can save your company money and reduce noise. Again, ask yourself “Is there a better way?”…..and the answer is YES, Casters off the ground.

Cut Expenses

This ties into the last point of reduced caster wear and are very simple….If your daughter cart’s casters see less wear because they are ALWAYS off the ground when in tow, you will not need to replace them near as often possibly never at all! Many of you know, a high-quality caster can make or break a system, and are not cheap to replace! This goes for just regularly scheduled maintenance as well. Less wear=less maintenance time and cost. Who doesn’t love saving money?!

Reduce Noise

Hear me out on this one (Do you see what I did there?). One of the least-discussed benefits to casters off the ground is the reduced noise levels associated with tugging. Simply put – when a Mother/Daughter cart train is being towed with casters on the ground you have wheels on a Mother Cart AND wheels on a Daughter Cart rattling around during towing. A caster OFF the ground Mother/Daughter system takes those Daughter Cart casters out of the equation.

Why is noise such a big deal? A noisy facility is a costly facility. OSHA’s regulations state where the worker is exposed to a weighted equivalent noise level of 85 dBA or more during an 8 hour shift the employer must implement a hearing conservation program. This includes consistently monitoring noise levels, offering free annual hearing tests, and providing hearing protection and training. If your decibel level is close to 85 dBA, having the right casters will make great improvements, but also having those casters off the ground could be the difference in being required to offer a costly hearing conservation program.

I hope this has helped to clarify why Mother/Daughter Cart systems with casters OFF the ground are optimal. Not only are they more efficient, but they can save your company money and reduce noise. Again, ask yourself “Is there a better way?”…..and the answer is YES, Casters off the ground.