Connecting Islands of Automation with CarryMatic

In the evolving landscape of industrial manufacturing, the pursuit of efficiency has led to the emergence of numerous automation technologies. However, a key challenge remains in seamlessly integrating these systems. Here is where Jtec comes into play with our innovative CarryMatic product line, designed to bridge the gaps between different stages of manufacturing. It transports from production lines to packaging, and beyond to storage and shipping docks.

Understanding the CarryMatic Product Line

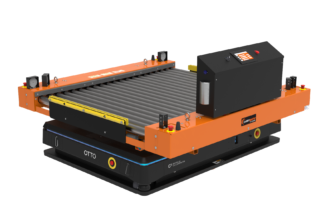

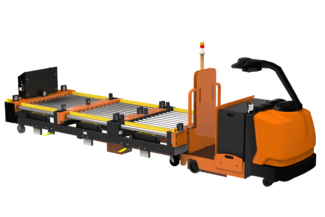

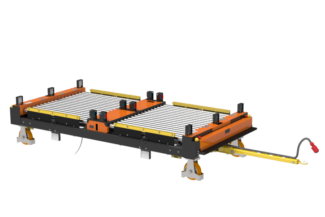

The CarryMatic system stands at the forefront of modern material handling solutions. Jtec’s CarryMatic carts can be pulled by an AGVs or mounted onto AMRs (Autonomous Mobile Robots) as attachments. Our Powered Roller carts and attachments are offered in both dual and single bay configurations. These can accept pallets at any stage of product development and transport them, hands-free, to the next. Additionally, our Scissor Lift attachment has a 9” lift stroke, and seamlessly transports pallets or specially made carts.

Unlike traditional material handling methods, CarryMatic’s state-of-the-art technology can be seamlessly integrated with your existing equipment to transform your material movements.

Islands of Automation in Manufacturing

Often, manufacturing facilities are plagued by ‘Islands of Automation’ – various systems operating independently, heavily relying on human intervention for manual transport and feed – a major cause of inefficiencies and even accidents. Islands can range from production lines to packaging stations, each requiring a nuanced approach to integration. CarryMatic turns these isolated islands into one seamless system. In today’s competitive landscape, the integration of these systems is not only beneficial but essential for increased safety, profit, and productivity.

Connecting the Dots with CarryMatic

CarryMatic is designed to address the very challenge of integrating these islands. By providing a seamless link between different stages of manufacturing, CarryMatic not only enhances efficiency but also ensures safety and scalability. We will help you connect the dots: our team will conduct an on-site analysis with you to design the ideal solution that meets your requirements. Through real-life applications, customers have seen how CarryMatic revolutionizes workflows, reduces manual interventions, and optimizes production timelines.

From Production to Shipping

One of the most critical transitions in manufacturing is from production to packaging. CarryMatic allows facilities to automate this transition, minimizing errors, and maximizing output. However, the automation journey doesn’t end at packaging. CarryMatic extends its capability to transport products to and from stretch wrapping, storage, and even shipping docks. This all-encompassing approach ensures that materials move consistently through each stage, reducing lead times and cutting costs.

The Future of Manufacturing Automation with CarryMatic

Additionally, the integration of data analytics and IoT stands to enhance its capabilities, offering more detailed insights and greater control over the manufacturing process. With a large and skilled team of R&D engineers, Jtec Industries has committed itself to utilizing and understanding the data to enhance the functionality, efficiency, and safety of material transportation in manufacturing. The future is here, and the time to enhance your process is now.

Conclusion

Altogether, connecting the various islands of automation in manufacturing is imperative for the future of the industry. Jtec Industries’ CarryMatic emerges as a pivotal player, offering solutions that streamline and enhance material handling. As we look toward a more interconnected and automated future, the necessity of a system like CarryMatic in achieving your goals cannot be overstated.

To learn more about how the CarryMatic product line, fill out the contact form below or visit our website. It’s time to embrace the future of manufacturing automation!