Why Mapping Material Movements Matters

It is not uncommon for any of us at Jtec Industries to stand with a LEAN Specialist or Manufacturing Engineer on a walkway overlooking the hectic pace of an operation below. Most often, our perch partner is shaking his/her head as, together, we watch several forklifts make many runs at speeds that would likely be frowned upon by OSHA. That’s why mapping material movement is an important step toward a better functioning workflow.

Some of the fork trucks carry a load, some not, some go forward, some go backward. Some move on a straight path, others zoom around corners.

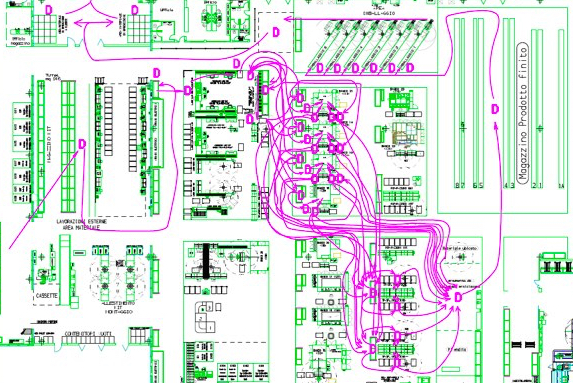

The diagram seen to the left, is the real-time representation of our customer’s spaghetti diagram. The diagram has so many lines it becomes impossible to interpret.

Creating a spaghetti diagram is the visual creation of actual flow. The keyword is ACTUAL, not what it should be or perceived to be. It is a snapshot in time so it may not include all what-if and special scenarios, but these do warrant discussion as the team progresses. The idea is to make quick and vigorous improvements to the Spaghetti Diagram with zero tolerance for waste.

Source: https://www.six-sigma-material.com/Spaghetti-Diagram.html

To accomplish this, process-flow specialists often employ Jtec Industries’ CarryMore Mother/Daughter Cart System with unique-in-the-industry, patented capabilities.

How CarryMore Can Help

CarryMore allows for material to move about within an organization (manufacturing or warehousing) without the need for forklifts. With a bit of route planning, most materials can be picked up and delivered via a train of carts making a continuous, circuitous route(s).

With CarryMore, mapping material movements become much easier and our customers enjoy the benefits of improved safety and efficiencies.

In LEAN terms, one might say the system turns a messy bowl of spaghetti into just one or two noodles!

At Jtec, we simply refer to the process of transitioning from forklifts to carts as “Going Fork Free.” Each of us at Jtec sincerely enjoys helping customers maximize the efficiency of mapping material movements while simultaneously contributing to employee safety within operations.

Contact Jtec Industries for more information about how you too can begin realizing the many benefits of CarryMore by Going Fork Free.