In many parts yards and industrial facilities, efficiency is lost in the constant back-and-forth. Moving one part at a time from parts storage to the production floor slows operations, ties up equipment, and wastes valuable labor hours. The most productive operations eliminate these extra trips—picking full tickets directly at the source with the right material handling hoist.

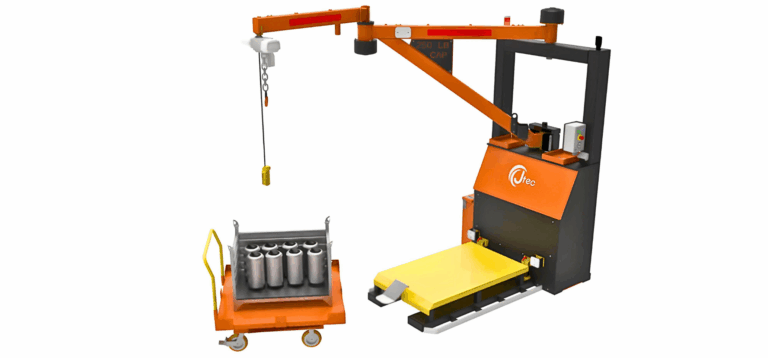

Jtec Industries’ Mobile Hoist is designed for exactly that. This portable lifting equipment works both indoors and outdoors, combining heavy-duty capacity with precise operator control. It enables live loading of parts directly onto pallets, crates, or carts, making full ticket completion possible right in the yard.

1) Frequent Trips That Eat Into Production Time

Operators often make multiple runs from storage to the facility for a single order. This constant back-and-forth not only slows order completion but also pulls labor away from other critical tasks.

2) Operator Strain from Awkward or Repetitive Lifts

Manual handling of large, heavy, or awkward parts takes a toll on operators. Frequent bending, twisting, or lifting increases fatigue and the likelihood of injuries, reducing overall productivity.

3) Extra Handling That Risks Part Damage

Parts that are picked, staged, and moved multiple times face higher chances of scratches, dents, or mechanical damage. This is especially costly for high-value or precision components.

4) Low Efficiency from Single-Part Handling

Without the ability to consolidate multiple picks into a single trip, throughput drops. This slows production support, forces more equipment use, and increases operating costs.

5) Reduced Workflow Visibility and Control

When picks are completed in multiple stages instead of in a single, direct process, managers have less real-time insight into job status. Delays or shortages often aren’t discovered until production is already impacted.

To Summarize:

Issues unanimously faced by yard pickers include:

- — Frequent trips from storage to facility that eat into production time

- — Congested equipment lanes from repeated short runs

- — Operator strain from awkward or repetitive lifts

- — Extra handling that risks part damage

These challenges slow throughput and make workflows inconsistent, especially in large parts yard operations.

1) Frequent Trips That Eat Into Production Time

Operators often make multiple runs from storage to the facility for a single order. This constant back-and-forth not only slows order completion but also pulls labor away from other critical tasks.

2) Operator Strain from Awkward or Repetitive Lifts

Manual handling of large, heavy, or awkward parts takes a toll on operators. Frequent bending, twisting, or lifting increases fatigue and the likelihood of injuries, reducing overall productivity.

3) Extra Handling That Risks Part Damage

Parts that are picked, staged, and moved multiple times face higher chances of scratches, dents, or mechanical damage. This is especially costly for high-value or precision components.

4) Low Efficiency from Single-Part Handling

Without the ability to consolidate multiple picks into a single trip, throughput drops. This slows production support, forces more equipment use, and increases operating costs.

5) Reduced Workflow Visibility and Control

When picks are completed in multiple stages instead of in a single, direct process, managers have less real-time insight into job status. Delays or shortages often aren’t discovered until production is already impacted.

To Summarize:

Issues unanimously faced by yard pickers include:

- — Frequent trips from storage to facility that eat into production time

- — Congested equipment lanes from repeated short runs

- — Operator strain from awkward or repetitive lifts

- — Extra handling that risks part damage

These challenges slow throughput and make workflows inconsistent, especially in large parts yard operations.

The Mobile Hoist is built to give operators more than just lifting power—it’s designed to streamline every step of the parts picking process, from first contact in the yard to final delivery at the facility. Its combination of heavy-duty strength, operator-focused ergonomics, and adaptability makes it an ideal tool for large-scale industrial and manufacturing environments.

Live loading at the pick point

Firstly, our hoist makes live loading at the pick point a reality. Instead of moving one part at a time or staging items in temporary holding areas, operators can place parts directly onto pallets, storage crates, or carts—allowing full ticket completion in one continuous pass. This reduces equipment traffic, eliminates wasted time, and helps maintain a steady workflow from yard to production.

350 lbs lifting power for ergonomic handling

The hoist is built with ergonomics in mind. It allows workers to load multiple heavy parts onto the platform, thereby reducing the need for multiple trips.

Positioning parts accurately with the 90° sweep boom

Allows operators to swing the boom precisely into position, making it easier to load into tight spaces, pallets, crates, or carts without unnecessary adjustments.

Quick relocation with the forkable base

Designed to move effortlessly between yard zones or facility areas using a forklift, keeping the hoist available wherever it’s needed most.

Safe, controlled operation via deadman pendant control

Gives operators precision control over every lift and movement, reducing the risk of mishandling or damage to high-value components.

OPA Version for loading directly onto carts

The OPA version of Jtec’s Mobile Hoist is equipped with an innovative locking mechanism, allowing the carts to be locked into the deck for quick and easy picking.

The Mobile Hoist is built to give operators more than just lifting power—it’s designed to streamline every step of the parts picking process, from first contact in the yard to final delivery at the facility. Its combination of heavy-duty strength, operator-focused ergonomics, and adaptability makes it an ideal tool for large-scale industrial and manufacturing environments.

Live loading at the pick point

Firstly, our hoist makes live loading at the pick point a reality. Instead of moving one part at a time or staging items in temporary holding areas, operators can place parts directly onto pallets, storage crates, or carts—allowing full ticket completion in one continuous pass. This reduces equipment traffic, eliminates wasted time, and helps maintain a steady workflow from yard to production.

350 lbs lifting power for ergonomic handling

The hoist is built with ergonomics in mind. It allows workers to load multiple heavy parts onto the platform, thereby reducing the need for multiple trips.

Positioning parts accurately with the 90° sweep boom

Allows operators to swing the boom precisely into position, making it easier to load into tight spaces, pallets, crates, or carts without unnecessary adjustments.

Quick relocation with the forkable base

Designed to move effortlessly between yard zones or facility areas using a forklift, keeping the hoist available wherever it’s needed most.

Safe, controlled operation via deadman pendant control

Gives operators precision control over every lift and movement, reducing the risk of mishandling or damage to high-value components.

OPA Version for loading directly onto carts

The OPA version of Jtec’s Mobile Hoist is equipped with an innovative locking mechanism, allowing our CarryMore carts to be locked into the deck for quick and easy picking.

To Summarize:

With Jtec’s Mobile Hoist, operations teams gain a measurable boost in efficiency and safety:

— Fewer trips and faster cycle times

— Increased throughput without extra staffing

— Reduced idle equipment time and congestion

— Better part protection with less handling.

— Safer, more ergonomic lifts for operators

The Mobile Hoist transforms yard picking from a repetitive, time-consuming task into a streamlined, high-performance process. For managers looking to boost productivity while protecting both people and parts, it delivers results from day one.

To Summarize:

With Jtec’s Mobile Hoist, operations teams gain a measurable boost in efficiency and safety:

— Fewer trips and faster cycle times

— Increased throughput without extra staffing

— Reduced idle equipment time and congestion

— Better part protection with less handling.

— Safer, more ergonomic lifts for operators

The Mobile Hoist transforms yard picking from a repetitive, time-consuming task into a streamlined, high-performance process. For managers looking to boost productivity while protecting both people and parts, it delivers results from day one.